Ciddiyaha Madow ee Shubka leh ee Stripe

Codsiga

Ciddiyaha Shubka Madow waxaa si weyn loogu isticmaalaa hawlo dhisme oo kala duwan, gaar ahaan kuwa ku lug leh shaqada sibidhka ama dhagaxa. Hadday tahay qaab-dhismeedka, rakibidda xariijinta looxa, ama isku xirka sanduuqyada korontada, musmaarradani waa kuwo lagu kalsoonaan karo oo hufan. Barta fiiqan iyo dhismaha birta adag waxay u oggolaanayaan rakibid aan kala go 'lahayn oo aan u baahnayn qodis hore, taasoo badbaadinaysa waqti iyo dadaal. Intaa waxaa dheer, musmaarrada shubka madow waxay ku habboon yihiin in lagu xiro agabka alwaaxda ku salaysan sibidhka ama lebenka, taasoo ka dhigaysa qalab asaasi ah oo loogu talagalay nijaarrada iyo farsamoyaqaannada ka shaqeeya dhismayaasha bannaanka sida deyrarka, sagxadaha, iyo pergolas.

Muuqaalka

Mid ka mid ah sifooyinka ugu muhiimsan ee ciddiyaha shubka madow waa iska caabinta daxalka sare. Dahaarka oksaydhka madow ma aha oo kaliya inuu ku daro bilicdooda, laakiin sidoo kale wuxuu u shaqeeyaa sidii caqabad qoyaan, isagoo ka hortagaya miridhku. Hantidani waxay ka dhigtaa ciddiyaha shubka madow mid ku habboon in loo isticmaalo meelaha qoyan ama xeebaha halkaas oo ciddiyaha caadiga ah ay waqti ka dib mirqi karaan. Intaa waxaa dheer, birta adag ee loo isticmaalo dhismahooda waxay hubisaa xoog iyo waxqabad la isku halleyn karo, taasoo u oggolaanaysa inay u adkeystaan culaysyo culus iyo xaaladaha cimilada ee daran.

Astaamo kale oo xusid mudan waa fududaynta isticmaalkooda. Ciddiyaha shubka madow waxay leeyihiin meel fiiqan oo si fudud ugu dhex socota sibidhka, dhagaxa, ama dusha sare ee alwaaxa. Looma baahna in godad hore loo qodo waxay badbaadisaa waqtiga waxayna si dhakhso ah u dhammaystiri kartaa mashaariicda. Intaa waxaa dheer, dahaarka madow wuxuu bixiyaa dhammaystir qurux badan oo xirfad leh, taasoo ka dhigaysa ciddiyahan kuwo ku habboon isticmaalka meelaha muuqaalkoodu muhiim yahay.

Waxyaabaha Agabka ah

| Sus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Noocyada Wire-ka ee Dalal Kala Duwan

| mm | CN.WG | SWG | BWG | AS.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Ciddiyaha Naqshadeynta Gaarka ah

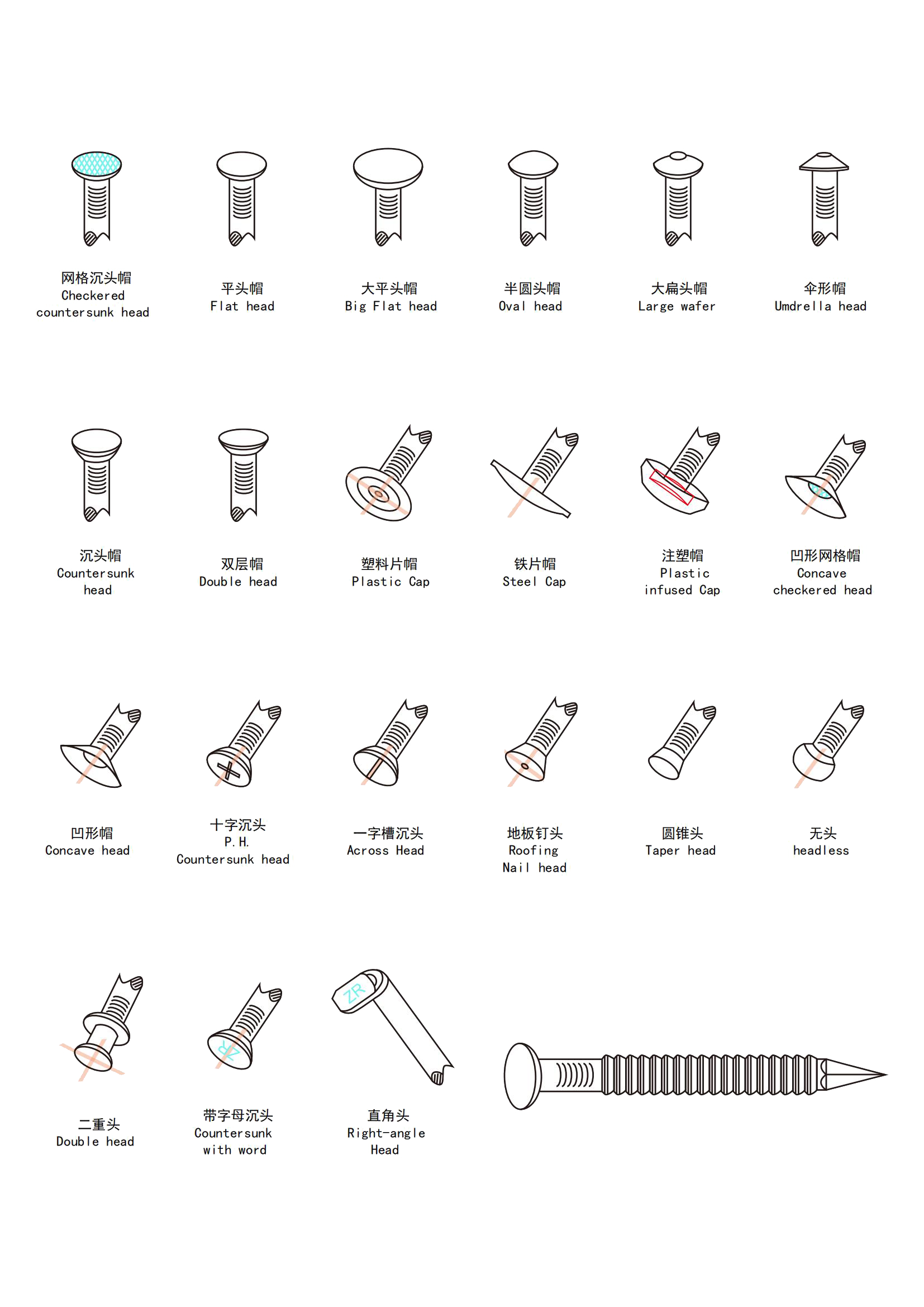

Nooca iyo Qaabka Madaxa Ciddiyaha

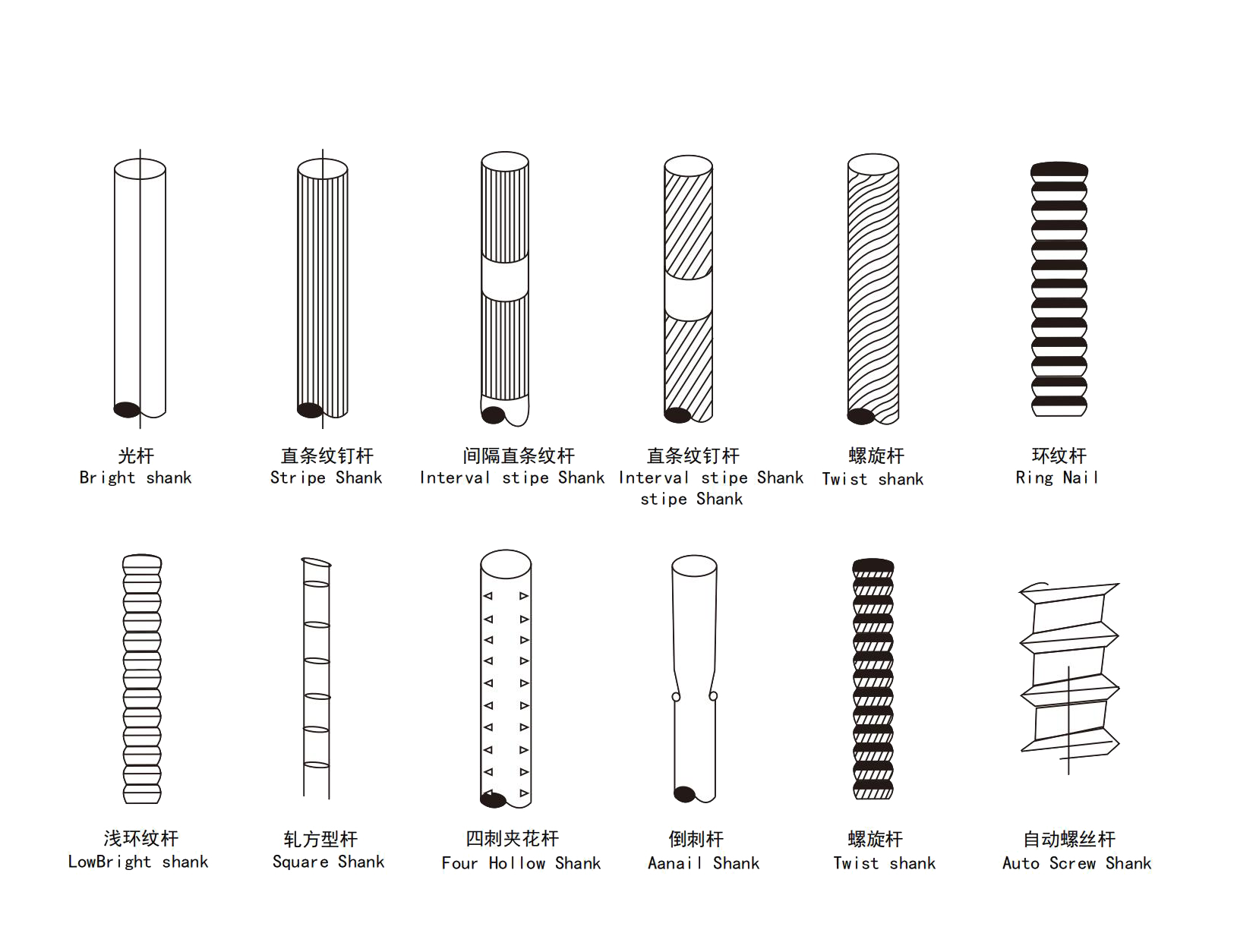

Nooca iyo Qaabka Ciddiyaha

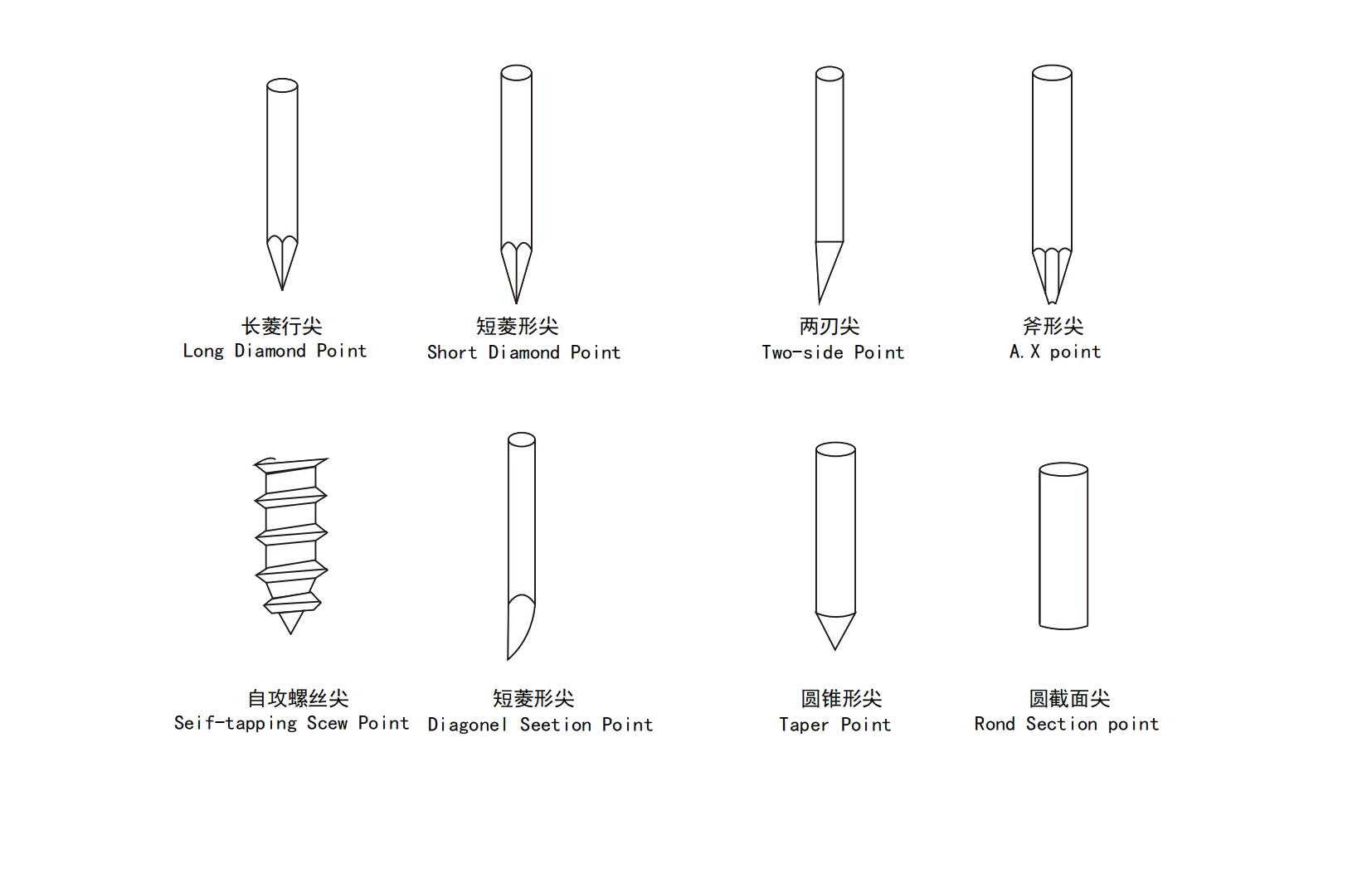

Nooca iyo Qaabka Barta Ciddiyaha

Yihe Enterprise waa shirkad ku takhasustay naqshadeynta iyo soo saarista ciddiyaha, ciddiyaha afargeeslaha ah, ciddiyaha duuban, dhammaan noocyada ciddiyaha qaabaysan iyo boolal. Xulashada walxaha ciddiyaha ee birta kaarboonka tayo leh, naxaasta, aluminiumka iyo birta aan miridhku lahayn, waxayna samayn kartaa daawayn galvanized, kulul, madow, naxaas iyo daawayn dusha sare ah iyadoo loo eegayo baahida macaamiisha. Boolal ugu weyn si loo soo saaro boolal mashiinka oo laga sameeyay Mareykanka ANSI, boolal mashiinka BS, bool corrugated, oo ay ku jiraan 2BA, 3BA, 4BA; boolal mashiinka oo laga sameeyay Jarmalka DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Taxanaha iyo noocyada kale ee alaabada caadiga ah iyo kuwa aan caadiga ahayn sida boolal mashiinka iyo dhammaan noocyada boolal mashiinka naxaasta ah.

Badeecaddeenna waxaa loo isticmaali karaa alaabta guriga ee xafiisyada, warshadaha maraakiibta, tareenka, dhismaha, warshadaha baabuurta. Iyada oo leh codsiyo ballaaran oo ku habboon qaybaha kala duwan, badeecadeennu waxay ka soo baxdaa tayo gaar ah - oo lagu sameeyay agab heer sare ah iyo farsamooyin wax soo saar oo horumarsan si loo hubiyo waarta iyo shaqeynta ugu wanaagsan. Intaa waxaa dheer, waxaan haynaa kayd ku filan mar walba, si aad ugu raaxaysato keenis degdeg ah oo aad uga fogaato dib u dhac ku yimaada mashaariicdaada ama hawlaha ganacsigaaga, iyadoon loo eegin tirada dalabka.

Habka wax soo saarkeena waxaa lagu qeexaa farsamo gacmeed heer sare ah - oo ay taageerayaan tignoolajiyada horumarsan iyo farshaxanleyaal xirfad leh, waxaan hagaajinaa tallaabo kasta oo wax soo saar ah si aan u hubinno saxnaanta iyo heerka sare ee badeecad kasta. Waxaan hirgelinnaa habraacyo xakameyn tayo oo adag oo aan meelna uga tagayn tanaasul: alaabta ceeriin ah si adag ayaa loo baarayaa, xuduudaha wax soo saarka si dhow ayaa loola socdaa, badeecadaha kama dambaysta ahna waxaa la mariyaa qiimeyn tayo oo dhammaystiran. Iyada oo ay ku saleysan tahay u heellan heer sare, waxaan ku dadaalnaa inaan farsameyno alaabooyin heer sare ah oo ka soo muuqda suuqa tayada sare iyo qiimaha waara.