Ciddiyaha Garaaca ee Shank Pallet

Codsiga

Ciddiyaha duuban ee loo yaqaan 'ring shank pallet' waxay si ballaaran ugu adeegsadaan warshado badan, gaar ahaan dhismaha iyo alwaaxa. Ku habboon in lagu xidho baallooyinka, sanduuqyada, agabka saqafka, sagxadaha hoose, iyo qaybaha kale ee dhismaha, ciddiyahani waxay bixiyaan qabsasho iyo xoog aan la barbar dhigi karin. Naqshadda garabka giraanta waxay ka hortagtaa in ciddiyaha ay dabacsanaadaan ama dib u soo noqdaan, taasoo hubinaysa daacadnimada waarta ee agabka la xidhay. Hadday tahay inaad dhisayso sagxad, rakibidda sagxad hoose, ama dhisidda qaab alwaax ah, ciddiyaha duuban ee garabka giraanta waa doorasho la isku halleyn karo si aad u sugto mashruucaaga si kalsooni leh.

Muuqaalka

1. Awoodda Qabashada Sare: Iyada oo ay ugu wacan tahay qaab-dhismeedka shanka giraantooda, ciddiyahani waxay bixiyaan awood hayn oo heer sare ah, iyagoo ka sarreeya kan ciddiyaha siman. Faraantiyadu si wax ku ool ah ayay u qabtaan fiilooyinka alwaaxda, iyagoo yareynaya fursadaha ka-noqoshada waxayna abuurayaan xiriir adag.

2. Waara: Laga sameeyay bir tayo sare leh, ciddiyaha duuban ee loo yaqaan 'ring shank pallet' waa kuwo aad u waara oo u adkaysta laabashada ama qalloocinta. Waaragani wuxuu hubinayaa in ciddiyaha ay u adkeysan karaan culaysyo culus iyo walxo adag iyagoon wax u dhimin waxqabadkooda.

3. Rarid Waxtar leh: Qaabka gariiradda ee ciddiyahan ayaa u oggolaanaya in si hufan loogu raro qoryaha ciddiyaha. Tani waxay meesha ka saaraysaa baahida loo qabo in si joogto ah loo raro, iyadoo la badbaadinayo waqtiga iyo kordhinta wax soo saarka inta lagu jiro hawlgallada xidhitaanka.

4. Kala Duwanaanshaha: Ciddiyaha duuban ee loo yaqaan 'ring shack pallet' waxaa laga heli karaa dherer iyo cabbirro kala duwan, iyagoo u adeegaya codsiyo iyo agab kala duwan. Kala Duwanaanshahani wuxuu hubinayaa in ay jirto cabbir ku habboon shuruud kasta oo gaar ah, taasoo u oggolaanaysa natiijooyin ku habboon.

Waxyaabaha Agabka ah

| Sus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Noocyada Wire-ka ee Dalal Kala Duwan

| mm | CN.WG | SWG | BWG | AS.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Ciddiyaha Naqshadeynta Gaarka ah

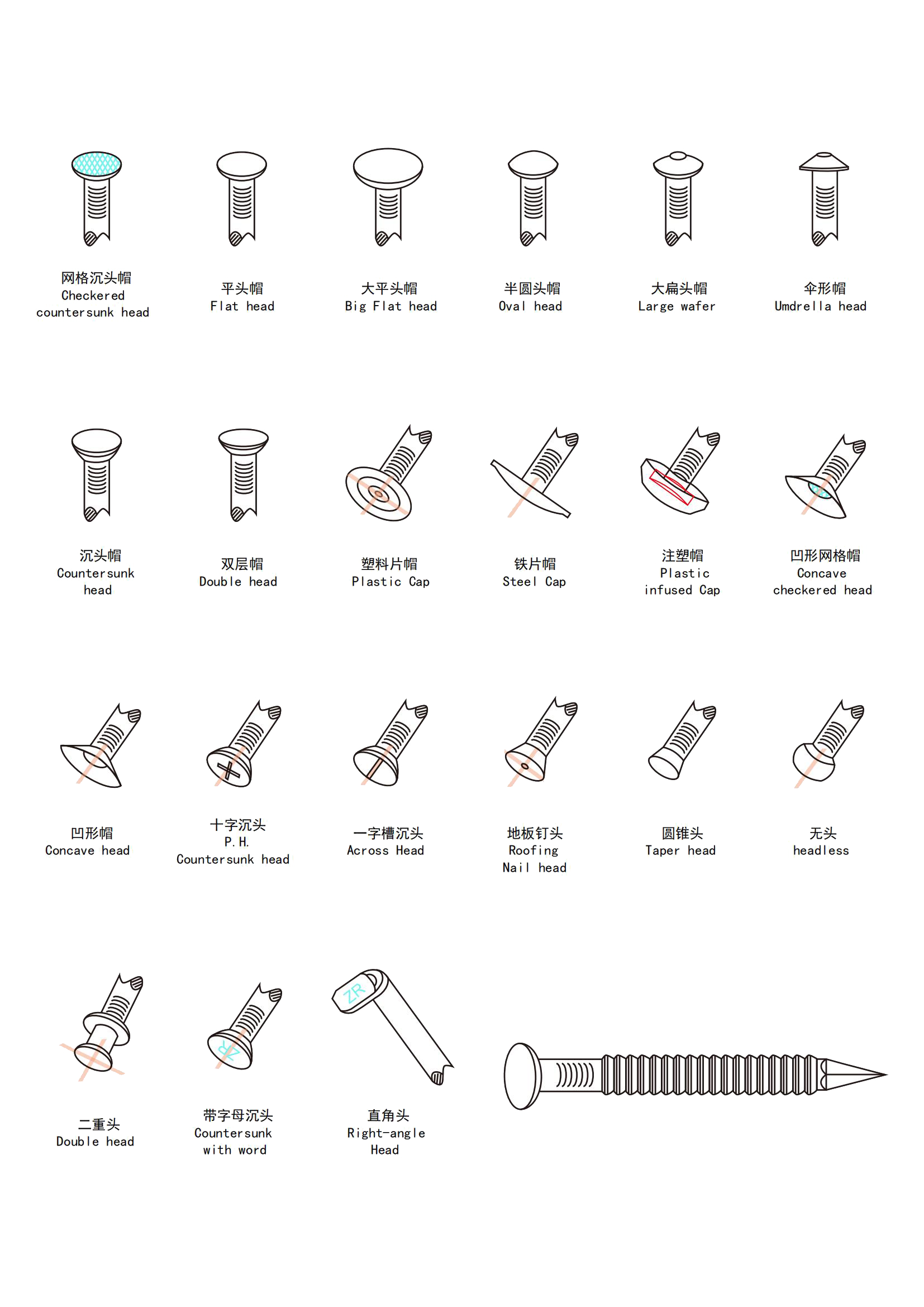

Nooca iyo Qaabka Madaxa Ciddiyaha

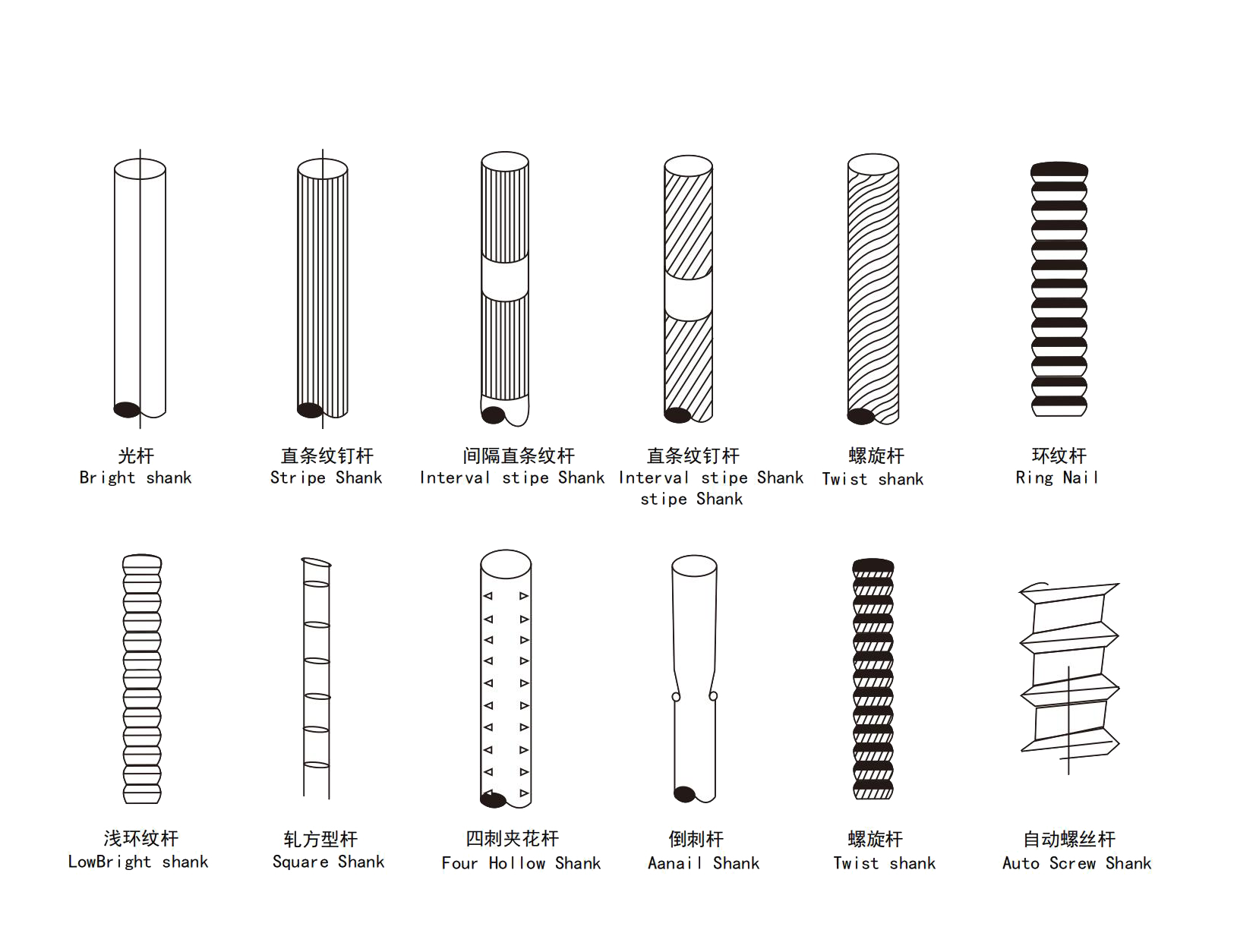

Nooca iyo Qaabka Ciddiyaha

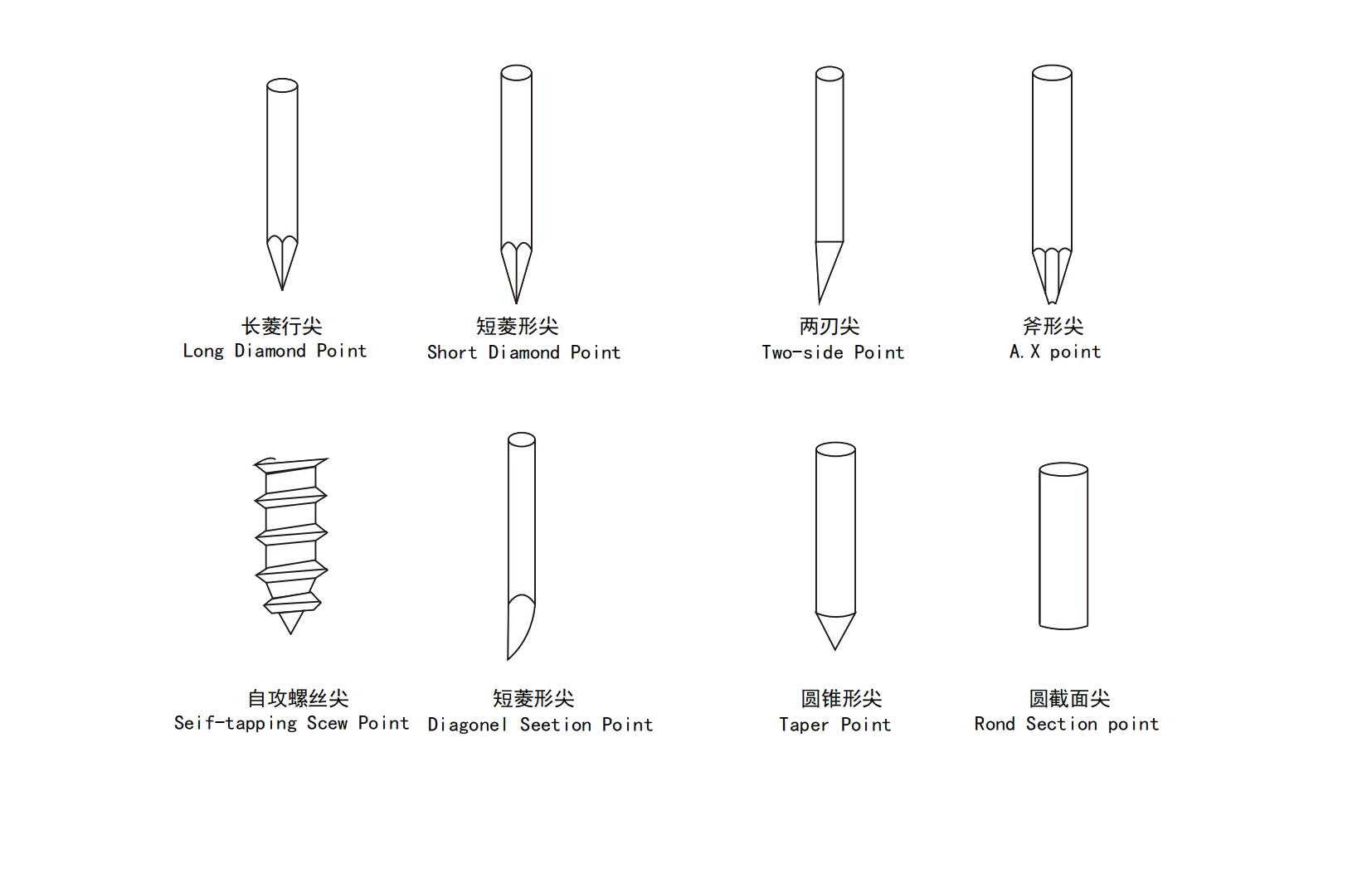

Nooca iyo Qaabka Barta Ciddiyaha

Yihe Enterprise waa shirkad ku takhasustay naqshadeynta iyo soo saarista ciddiyaha, ciddiyaha afargeeslaha ah, ciddiyaha duuban, dhammaan noocyada ciddiyaha qaabaysan iyo boolal. Xulashada walxaha ciddiyaha ee birta kaarboonka tayo leh, naxaasta, aluminiumka iyo birta aan miridhku lahayn, waxayna samayn kartaa daawayn galvanized, kulul, madow, naxaas iyo daawayn dusha sare ah iyadoo loo eegayo baahida macaamiisha. Boolal ugu weyn si loo soo saaro boolal mashiinka oo laga sameeyay Mareykanka ANSI, boolal mashiinka BS, bool corrugated, oo ay ku jiraan 2BA, 3BA, 4BA; boolal mashiinka oo laga sameeyay Jarmalka DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); GB Taxanaha iyo noocyada kale ee alaabada caadiga ah iyo kuwa aan caadiga ahayn sida boolal mashiinka iyo dhammaan noocyada boolal mashiinka naxaasta ah.

Badeecaddeenna waxaa loo isticmaali karaa alaabta guriga ee xafiisyada, warshadaha maraakiibta, tareenka, dhismaha, warshadaha baabuurta. Iyada oo leh codsiyo ballaaran oo ku habboon qaybaha kala duwan, badeecadeennu waxay ka soo baxdaa tayo gaar ah - oo lagu sameeyay agab heer sare ah iyo farsamooyin wax soo saar oo horumarsan si loo hubiyo waarta iyo shaqeynta ugu wanaagsan. Intaa waxaa dheer, waxaan haynaa kayd ku filan mar walba, si aad ugu raaxaysato keenis degdeg ah oo aad uga fogaato dib u dhac ku yimaada mashaariicdaada ama hawlaha ganacsigaaga, iyadoon loo eegin tirada dalabka.

Habka wax soo saarkeena waxaa lagu qeexaa farsamo gacmeed heer sare ah - oo ay taageerayaan tignoolajiyada horumarsan iyo farshaxanleyaal xirfad leh, waxaan hagaajinaa tallaabo kasta oo wax soo saar ah si aan u hubinno saxnaanta iyo heerka sare ee badeecad kasta. Waxaan hirgelinnaa habraacyo xakameyn tayo oo adag oo aan meelna uga tagayn tanaasul: alaabta ceeriin ah si adag ayaa loo baarayaa, xuduudaha wax soo saarka si dhow ayaa loola socdaa, badeecadaha kama dambaysta ahna waxaa la mariyaa qiimeyn tayo oo dhammaystiran. Iyada oo ay ku saleysan tahay u heellan heer sare, waxaan ku dadaalnaa inaan farsameyno alaabooyin heer sare ah oo ka soo muuqda suuqa tayada sare iyo qiimaha waara.